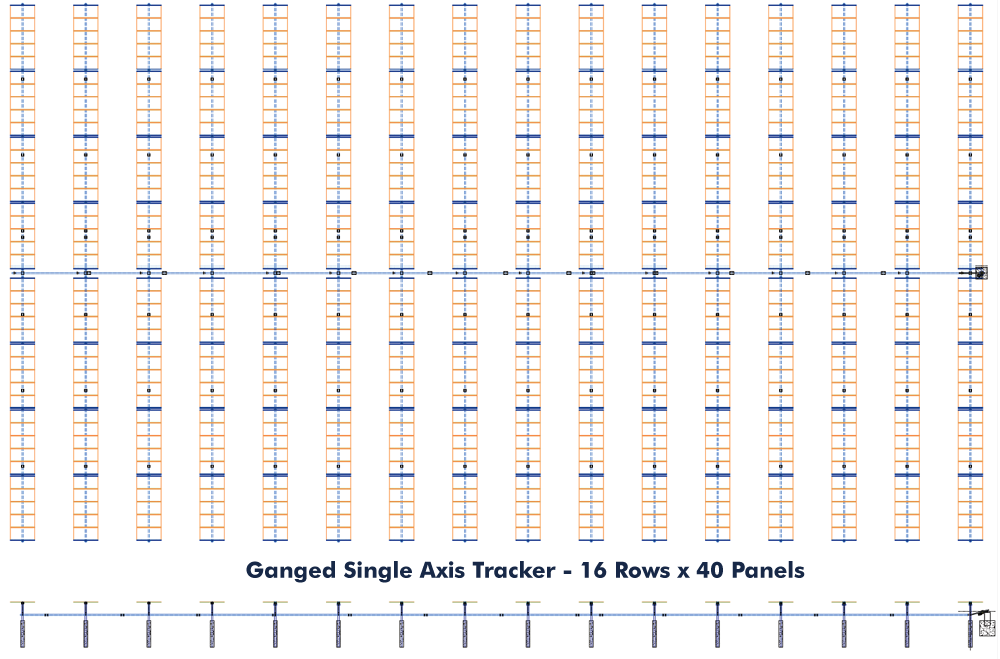

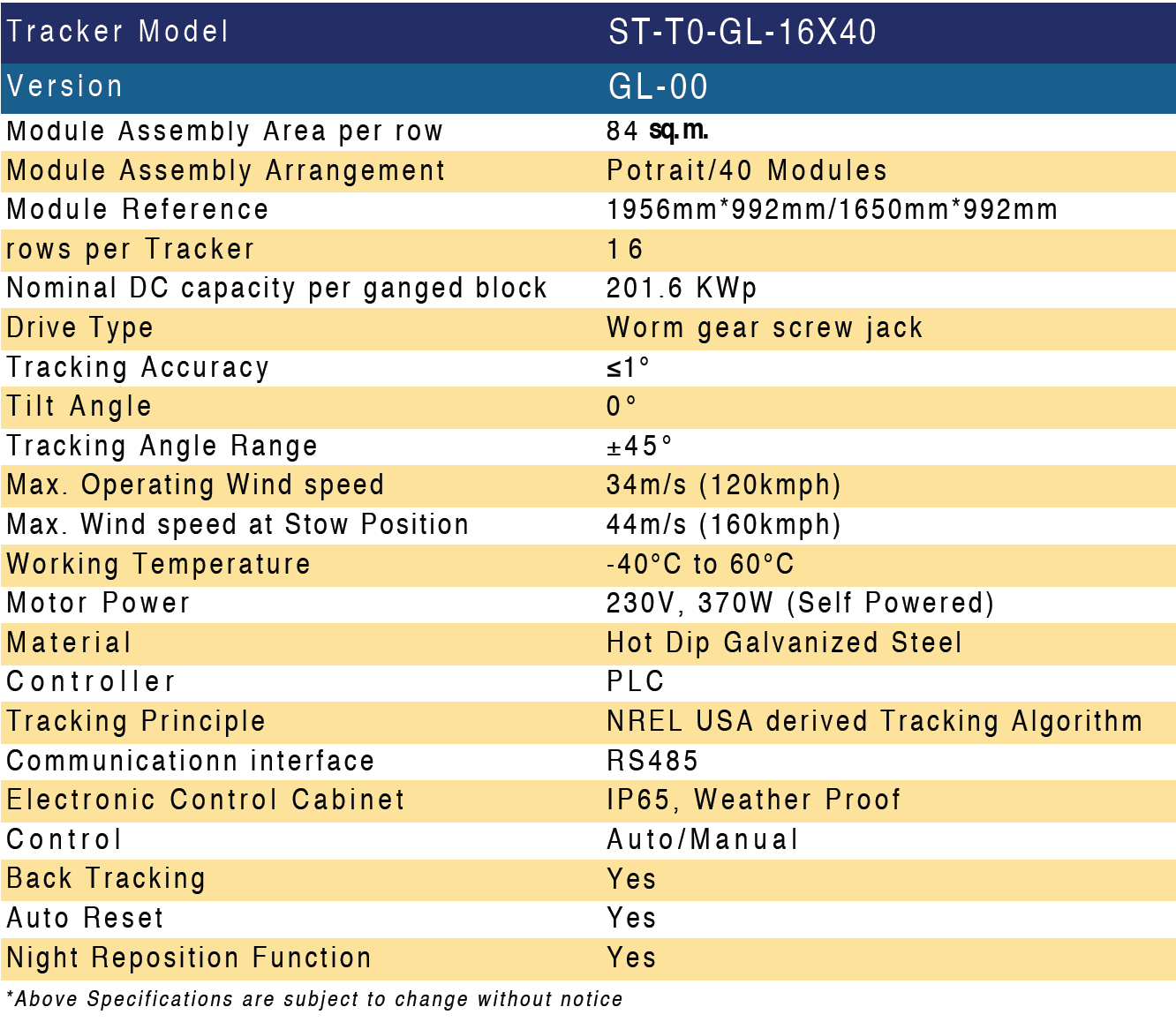

A maximum of 16 rows are ganged together mechanically. The ganged rows are driven by a single linear actuator (worm gear screw jack) with 0.5 Hp capacity AC motor. A maximum of 40 modules can be mounted on each tracker row. The sun is tracked from east to west with provision for back tracking to avoid proximal shadow losses.

PTFE bearings used in the tracker are maintenance free and long lasting.

Each controller manages two ganged tracker blocks.

Simple assembly and rapid installation results in reduction ofinstallation cost and compression of construction schedule.

The self-powered controller eliminates need for auxiliary AC power for actuator driving mechanism.

The intelligent back tracking algorithm within the tracker increases energy output by avoiding proximal shadows.